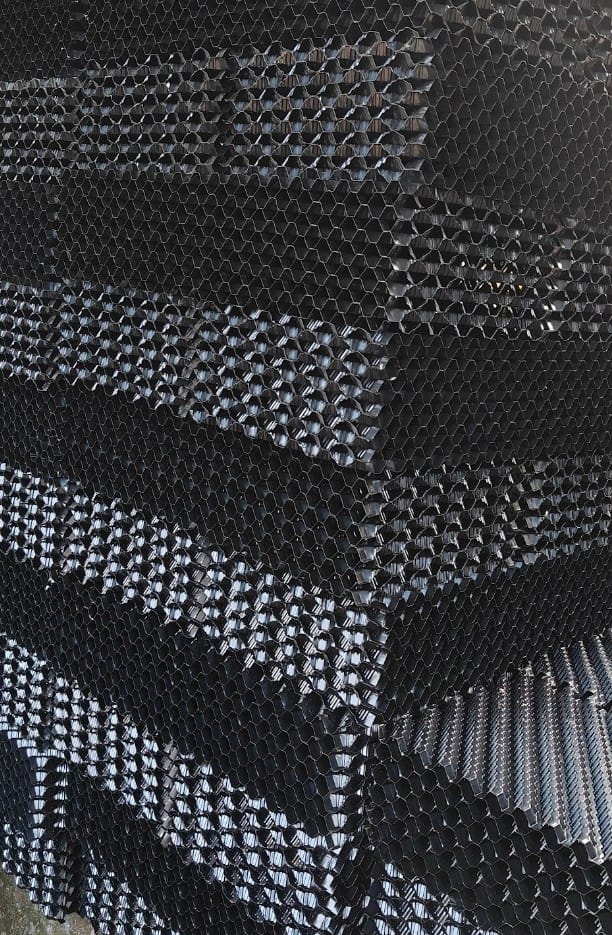

PVC Fills

PVC Fills

Arohi Engineering and Cooling Tower is into manufacture and marketing of various types of fill design suitable for different water quality. These fill Media are manufactured meeting CTI standards.

Advantage of AECT film fill.

- Continuous Forming: Continuous forming process allows free flow of material during the stage of formation. Additional requirement of raw material is met hence no thinning takes place at crests & troughs.

- Double Edge Folding: MM Aqua’s manufacturing technique has the ability to fold the edges of the sheets providing stronger edges, which gives extra protection against water loads and shear force form beams. It also protects the fill from damages during installation & maintenance.

- Uniform Thickness: Provides uniform strength in fill sheets all along the fill surface.

- Micro structure: Unique shape and dimension provides long retention time and thus longer time for heat transfer.

- Longer Length: Allows the structural designer to reduce number of support beam thus intern reduces the pressure drop and cost of construction

Technical Data:

|

Characteristics |

Units |

AECT-12 |

AECT -19 |

AECT -27 |

|

Cooling Towers Application |

Counterflow |

Counterflow |

Counterflow |

|

|

Flute height |

mm |

12 |

19 |

27 |

|

Longitudinal pitch |

mm |

38 |

50 |

70 |

|

Spiral angle |

°(degree) |

28 |

28 |

28 |

|

Std. sheet size |

mm x mm |

600x300 |

1200x300 |

1200x300 |

|

Max Fill Sheet size |

mm x mm |

1800 x 600 |

1800 x 600 |

1800 x 600 |

|

Surface area per unit volume |

M²/m³ |

250 |

158 |

120 |

|

Maximum continuous |

°C |

55 |

55 |

55 |

|

Standard Fill Sheet |

mm |

0.2 |

0.25 |

0.3 |

Item Code: 12mm-19mm